The current position: Home > Latest News > What is the difference between high temperature nylon PA6T/9T and PA46? >

The application of nylon has a long history. Since it was successfully developed by DuPont in 1939, it has been more than 60 years. Its earliest application is in fiber, which has many excellent properties. After the 1950s, engineering plastics replaced metal. With the rapid growth of the market, various specifications of nylon have been developed and put into practical use one after another.

Recently, due to the plasticization of electronic, motor parts, and auto parts, there are further requirements for their performance, especially in terms of heat resistance. Therefore, there are super engineering plastics. Heat-resistant nylons such as PA4-6 and PA6T are here. enter the market upon request.

01 Specifications and characteristics of PA46

1. Product Features

1. PA46 is a multi-purpose, glass-reinforced, flame-retardant UL grade material that meets UL VO regulations;

2. Has easy processing and excellent flow properties;

3. Has excellent tensile strength and good thermal insulation performance;

4. Flame retardant; electroplating; heat-stabilized; heat-resistant;

5. High stiffness retention performance, while showing good high temperature creep resistance;

6. Stiffness and creep modulus due to PPS, PEI and PES of the same glass reinforcement;

7. It can be used for parts with thin wall parts up to 0.1mm without flash.

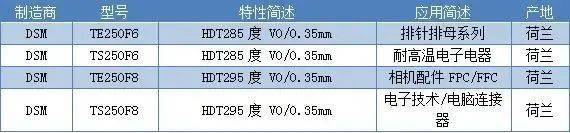

2. Product Specifications

02 Specifications, characteristics and applications of PA9T

1. Introduction of PA9T

KURARAY has developed a new specification of heat-resistant nylon (Polyamide 9T, trade name Genestar), which is obtained by polymerizing terephthalic acid of a linear aliphatic diamide of carbon number 9. It is the first new product in the world. product.

PA9T is a poly-1,9-nonylidene terephthalamide, which is different from general PA and has many unique properties. PA9T is a homopolymer with a semi-aromatic main chain and a long carbon chain (9 carbons) structure, which is relatively Another high temperature resistant nylon PA6T carbon chain (6 carbons) is long, similar high temperature resistant nylon has nylon Zytel HTN series of American Du Pont engineering polymer company and PPA (polyphthalamide of Belgium Solvay high performance polymer company) )Amodel. PA9T does not need to be modified to lower its melting point (306°C) before processing, while PA6T needs to be modified to lower its melting point to meet the requirements of injection molding. Another advantage of PA9T is its low water absorption, which is comparable to PBT and much lower than other PAs. Generally, the water absorption of PA46 is 10%, and that of PA66 is 15%, which is also lower than that of another semi-aromatic high-temperature nylon PA6T.

The high glass transition temperature (125℃) and high crystallinity of PA9T make it still have good toughness at high temperature, which is better than PA66 and PA46, and its abrasion resistance and friction coefficient (small) are much better than other nylons, even more than POM (Polyoxymethylene) and LCP (Liquid Crystal Polymer). Another excellent property of PA9T is its resistance to chemicals and fuels, alcohols, acids and calcium dichloride, hot water and other fluids, surpassing almost all PAs, only slightly worse than PPS (polyphenylene sulfide), and to fuel The barrier property of PA9T is ten times that of PA6 and PA12, which is close to the level of ETFE (ethylene-tetrachloroethylene copolymer). These good comprehensive properties make PA9T very suitable for the application of automobile under-hood products and computer accessories.

Genestar is better than other existing plastics in the balance of formability, heat resistance, dimensional stability, chemical resistance, and foldability, so it is used in electronics, motors, and automotive parts. The following is an explanation of its development background, material characteristics, specific uses and future prospects.

2. Product Features

1. Among the nylon series resins, the water absorption is the lowest;

2. Dimensional stability will not cause dimensional change and mechanical strength decrease due to water absorption;

3. High heat resistance, no bubbles will be generated in the tin test at 280 degrees, and it is also suitable for lead-free solder with higher operating temperature;

4. Good fluidity, suitable for thin meat forming;

5. Low gas, less likely to pollute and corrode the mold than other nylon resins, and prolong the use of the mold;

6. Fast crystallization speed and short cooling time;

7. In a high temperature environment, the mechanical strength and rigidity decrease less, and the bonding wire strength and recyclability are good.

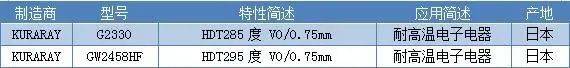

3. Product Specifications

The melting point of PA6T is 320 degrees.

The melting point of PA46 is 295 degrees.

The melting point of PA9T is 306 degrees.

In injection molding, PA46 and PA9T are relatively easy to control. They can be molded when the temperature does not have to be reached. The HDT value of 6T is very close to the melting point. The HDT value is 305 and the melting point is 320 degrees. The difference between the two is relatively small , so it is difficult to control the temperature during molding (relative to 9T and 46). Then according to the calculation method of general injection mold temperature setting: glass transition temperature + 20-30 degrees = mold temperature, the mold temperature of PA6T must be set to more than 120 degrees.

The performance of PA6T is between 46 and 9T, which belongs to a moderate product. If the concept is blurred, the basic 6T can be used in the market of 46 and 9T, especially in the replacement of 9T, 6T has different specifications to correspond. For example, the ultra-low warpage specification EW630N of PA6T can replace the GW2458 of 9T, and the general specifications E430NT5 and E630N of PA6T can replace the GN2330 of PA9T, etc. For some connectors and other products made by 46, 6T can also be replaced accordingly.

A major disadvantage of PA46 is that the water absorption rate is too high and it is easy to foam, so now it has been changed to vacuum packaging, but its characteristics are still difficult to change. PA9T is rigid, brittle, and easy to be out of stock. It is in the process of halogen-free research and development. In this piece, the halogen-free specification tested by 9T in Foxconn broke two screws of Foxconn. Because of its injection molding process requirements, many people are willing to choose 9T for 6T, but now with the emergence of halogen-free materials and the strong R&D capabilities of Mitsui Chemicals, 6T will go to its previous market.