The current position: Home > Latest News > The blue ocean market for optical grade plastic parts is opening up >

Most optical plastics are thermoplastics, which are mainly used in larger batches of optical instruments to manufacture optical substrates, lenses, contact lenses, organic optical fibers, etc. Because optical plastics have the advantages of good plastic molding process characteristics, light weight, low cost, etc., optical plastics are currently used to manufacture optical parts, especially special optical parts are increasingly manufactured.

With the advancement of "Plastic Substitution of Glass", the market size of optical grade plastic parts has gradually exceeded 20 billion, which is a key equipment for the national "Independent Innovation Guidance Catalog for Major Technological Equipment". In addition, "plastics to replace glass" and "plastics to replace steel" are also one of the main trends in the development of auto parts. Compared with glass or steel, plastic has better molding advantages and is an important part of injection molds and hot runners.

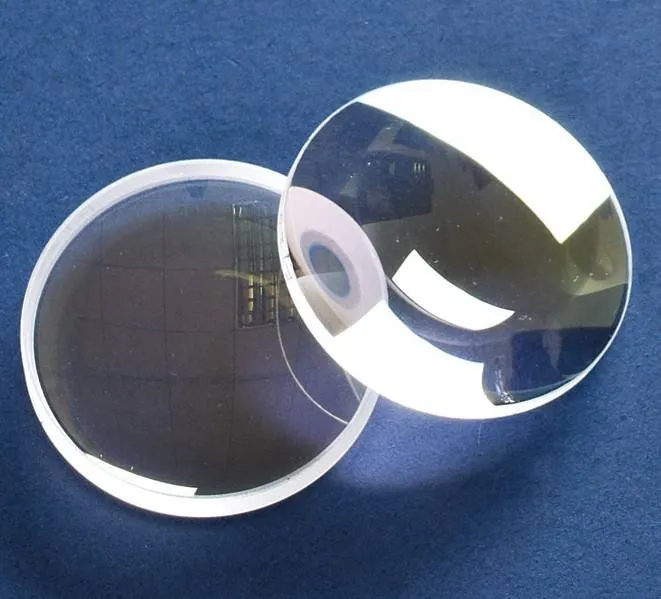

Compared with optical glass, optical lenses currently mainly use optical plastic materials and injection molding processes, and their advantages are low cost and light weight. Injection molding is the preferred solution for VR optical lenses. VR optical lenses can magnify the screen image and provide a suitable FOV (field of view) to help human eyes focus on the screen clearly and obtain better immersion effects. It is an important part of the VR system.