The current position: Home > Latest News > The National Energy Administration encourages all departments to make a good reserve of photovoltaic power station projects, which is beneficial to these materials >

On November 26, the Comprehensive Department of the National Energy Administration issued the "Administrative Measures for the Development and Construction of Photovoltaic Power Generation (Draft for Solicitation of Comments)" (hereinafter referred to as the "Measures") and publicly solicited opinions to further optimize the development and construction management of photovoltaic power stations and promote the continued growth of the photovoltaic power generation industry. Quality development.

With the continuous advancement of the "dual carbon" goal, the prosperity of the photovoltaic power generation industry will continue to rise. Today I will take you to understand what photovoltaic materials are? What are the raw materials of photovoltaic modules?

Photovoltaic materials [solar cell materials], also known as solar cell materials, refer to materials that can directly convert solar energy into electrical energy. Photovoltaic materials can generate current because of the photovoltaic effect, that is, if light shines on the solar cell and the light is absorbed in the interface layer, photons with sufficient energy can excite electrons from covalent bonds in P-type silicon and N-type silicon , Resulting in electron-hole pairs.

The materials that can be used as solar cell materials in photovoltaic materials include monocrystalline silicon, polycrystalline silicon, amorphous silicon, GaAs (gallium arsenide), GaAlAs (gallium aluminum arsenide), InP (indium phosphide), CdS (cadmium sulfide), CdTe (Cadmium telluride) and so on. Classified by application, there are monocrystalline silicon, GaAs, and InP used in space; monocrystalline silicon, polycrystalline silicon, and amorphous silicon have been mass-produced for ground use; other aspects are still in the development stage.

At present, in the field of photovoltaic materials, various practitioners are working to reduce material costs and improve conversion efficiency, so that the electricity price of solar cells will compete with that of thermal power generation, thereby creating conditions for wider and larger-scale applications.

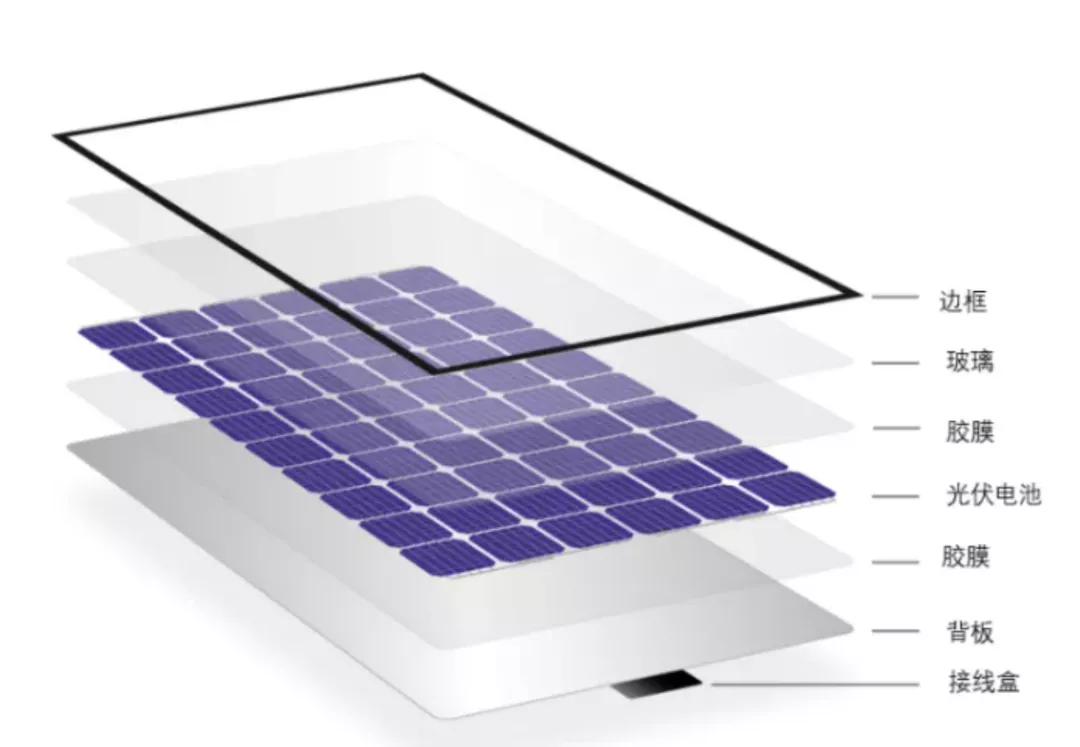

『光伏模组封装材料介绍』

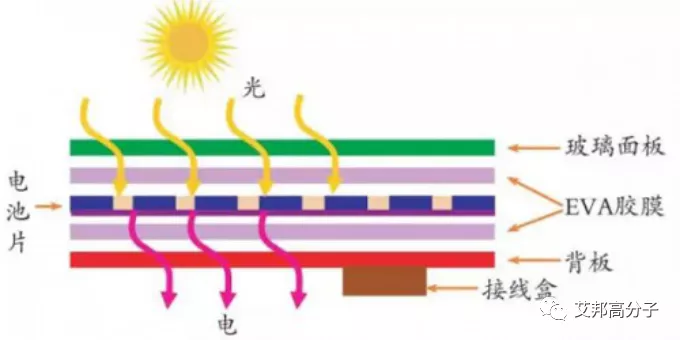

光伏模组结构示意图

Let’s take a look at the materials used for photovoltaic module packaging from top to bottom. First, the frame is made of metal materials to protect the laminate and play a role of sealing support. With the development of technology, metal materials can be made of plastic Instead, such as PPO (polyphenylene ether) + GF (glass fiber), in addition, Solvay's semi-aromatic polymers can also be used on the frame of photovoltaic modules.

The role of the glue film in the photovoltaic module is to glue the photovoltaic glass, the cell and the back sheet together, and at the same time protect the cell and isolate the air. The cost of the module is 3% to 4%.

The types of photovoltaic film include EVA material film and POE material film.

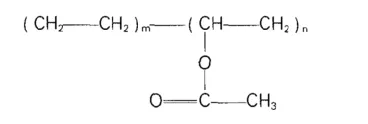

1EVA

EVA is made by copolymerization of ethylene and acetic acid. Chinese chemical name: ethylene-vinyl acetate copolymer (ethylene-vinyl acetate copolymer). Its performance mainly depends on the molecular weight (it can be expressed by the melt index M1) and vinyl acetate (in VA represents the content of). When M1 is constant, the content of VA increases, and the elasticity, flexibility, cohesiveness, compatibility and transparency of EVA increase; the content of VA decreases, and the performance of EVA is close to that of polyethylene. When the VA content is constant, the molecular weight decreases, the softening point decreases and the processability and surface gloss improve, but the strength decreases; the molecular weight increases, which can improve impact resistance and stress cracking resistance.

EVA分子结构式

In one sentence, EVA is a copolymer. High VA content tends to be elastomers and hot melt adhesives; if E content is high, it tends to plastics (PE).

The encapsulation film is made of EVA material, which is used to bond the solar cell in the crystalline silicon cell with the surface photovoltaic glass and the cell backplane. Because EVA film has good flexibility, optical transparency and heat sealability, it has become the first choice for photovoltaic packaging materials.

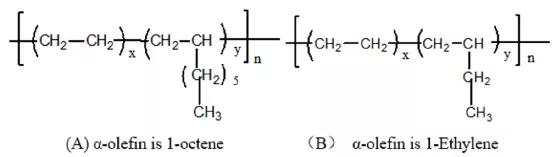

2POE

POE is a copolymer of ethylene and octene, in which the comonomer octene (C8H16) content is 20%-30%. The presence of octene in the molecular structure destroys the crystallization of ethylene, but at the same time it also gives the copolymer excellent transparency and good elasticity.

Ethylene crystallization at room temperature serves as a physical cross-linking point, and ethylene crystallization at high temperature makes the copolymer plastic. The narrow molecular weight distribution enables POE to have higher tensile strength and impact resistance.

POE分子结构示意图

Different from the EVA film materials most commonly used by photovoltaic module manufacturers, POE films have better electrical performance, lower water vapor transmission speed, and better weather resistance. POE can also greatly reduce the potential induced decay effect (PID), which is very suitable for N-type battery modules and double-glazed modules, and is becoming more and more popular.

『背板材料介绍』

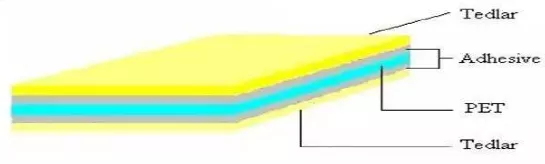

Backsheet is a photovoltaic packaging material used on the back of solar modules to directly contact the external environment on a large area. It should have excellent long-term aging resistance (humid heat, dry heat, ultraviolet), electrical insulation, and water vapor barrier properties. .

Therefore, the back film must meet the 25-year environmental test of solar cell modules in terms of aging resistance, insulation resistance, and moisture resistance, and play the role of encapsulating the raw materials of the components, protecting the solar modules, and isolating the bus belt.

背板所在位置示意图

Although the components of the backsheets of various manufacturers are different, the core parts will not change, that is, the PET matrix and fluorine-containing materials. PET provides mechanical properties and insulation properties, and fluorine materials provide barrier properties and weather resistance. The main characteristics of the backsheet are embodied by fluorine materials. Generally speaking, whether fluorine materials are composite films or coatings, as long as they are processed properly and the content of F is sufficient, the weather resistance and barrier properties of the backsheet are not a problem.

PET (polyethylene terephthalate), English name: polyethylene terephthalate, referred to as PET, commonly known as polyester, is a high polymer, derived from the dehydration and condensation reaction of ethylene terephthalate, and benzene Ethylene dicarboxylate is obtained by the esterification reaction of terephthalic acid and ethylene glycol.

The PET substrate is very single, but when it comes to fluorine materials, there are many types.

1PVF

PVF, the scientific name polyvinyl fluoride, is a copolymer extruded from a copolymer of fluorine and fluorocarbon molecules. The most famous PVF film is DuPont of the United States. DuPont's registered trademark TEDLAR is now the PVF film most used in the photovoltaic industry.

2PVDF

PVDF, the scientific name polyvinylidene fluoride, is currently the second largest product among fluorine-containing materials in terms of output. The most famous manufacturer of PVDF is Arkema in France. Arkema’s registered trademark KYNAR is now the PVDF film with the largest number of backsheets in the photovoltaic industry.

3THV

THV, tetrafluoroethylene-hexafluoropropylene-vinylidene fluoride copolymer, is a new type of fluorine-containing material developed by Dyneon in the United States in the 1980s and is applied to the BBF (THV/PET/EVA) backplane of 3M. , Is currently the only manufacturer, and now Dyneon has started operations as a subsidiary of 3M.

4ETFE

ETFE, ethylene-tetrafluoroethylene copolymer, ETFE film developed by Japan's Asahi Glass Co., Ltd., is completely self-produced from raw material to film, and has good weather resistance and chemical stability. However, the market usage is not large. Domestic backsheet manufacturers, Such as Lucky Company, some are used in batches.

5ECTFE

ECTFE, ethylene-chlorotrifluoroethylene copolymer, ECTFE was successfully developed by DuPont in 1946, and currently only a few companies such as Solvay can provide commercial products. ECTFE is a 1:1 alternating copolymer of ethylene and chlorotrifluoroethylene. It has the typical chemical resistance of fluoroplastics. No solvent can corrode ECTFE or cause stress cracking at 120°C, and it has high weather resistance. Sex and barrier properties.